Beyond BTU: The Thermal Mass Index and Why Your Radiator's Material is the Key to Smart Heating

The way we heat our homes in the United Kingdom is undergoing a quiet revolution. For generations, the calculation was simple: measure the room, look up a chart, and buy a white steel panel that matched the required output. We treated heating as a static requirement a simple box to be ticked during a renovation. However, with the rapid rise of energy prices, the introduction of Air Source Heat Pumps (ASHPs), and the ubiquity of smart home automation, the old rules no longer apply.

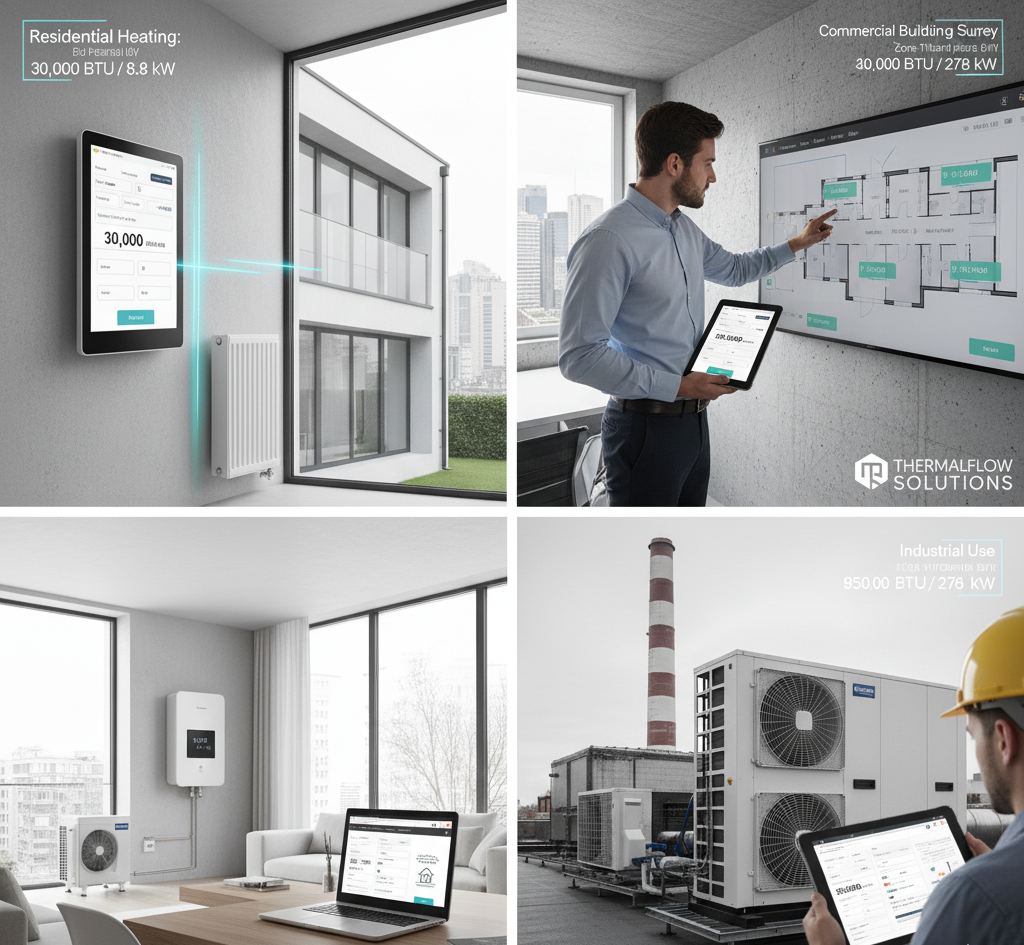

If you are currently shopping for a new heating system, you are likely fixated on one number: BTU (British Thermal Unit). It is the standard currency of our industry, representing the total energy required to raise the temperature of one pound of water by one degree Fahrenheit. While BTU is useful for sizing, it is fundamentally flawed in the modern context because it ignores the element of time. It tells you how much heat a unit can emit at full capacity, but it tells you nothing about the journey to get there.

This is where we need to introduce a new metric: the Thermal Mass Index (TMI). This concept moves beyond simple output to measure responsiveness. In a world where we micro-manage our heating zones via smartphone apps and demand instant comfort, the material composition of your heat emitter is critical. Specifically, the shift from heavy steel to a high-performance aluminium radiator is the single most effective upgrade you can make to future-proof your home, ensuring your system is not just powerful, but intelligent.

The Physics of Comfort: Why Material Matters

To understand why your choice of radiator is about more than just aesthetics, we have to look at the physics of the metals involved. When your central heating fires up, the water has to heat the metal body of the radiator before that radiator can heat the air. This creates a "lag time" in your comfort.

Traditional materials like cast iron and mild steel have a high density and a moderate specific heat capacity. They act like thermal sponges, soaking up vast amounts of energy before they begin to do their job. This was acceptable in the days of coal fires where heat needed to be smoothed out over a long day. However, in a modern home with high insulation levels, this "thermal inertia" is a liability.

Aluminium is different. It possesses a unique combination of low density and high thermal conductivity. In fact, aluminium conducts heat approximately four times more efficiently than mild steel. This means that the moment hot water enters the core of the radiator, the energy is transferred to the surface almost instantaneously. There is no "soaking" period. There is no waiting. There is just immediate warmth.

Defining the Thermal Mass Index (TMI)

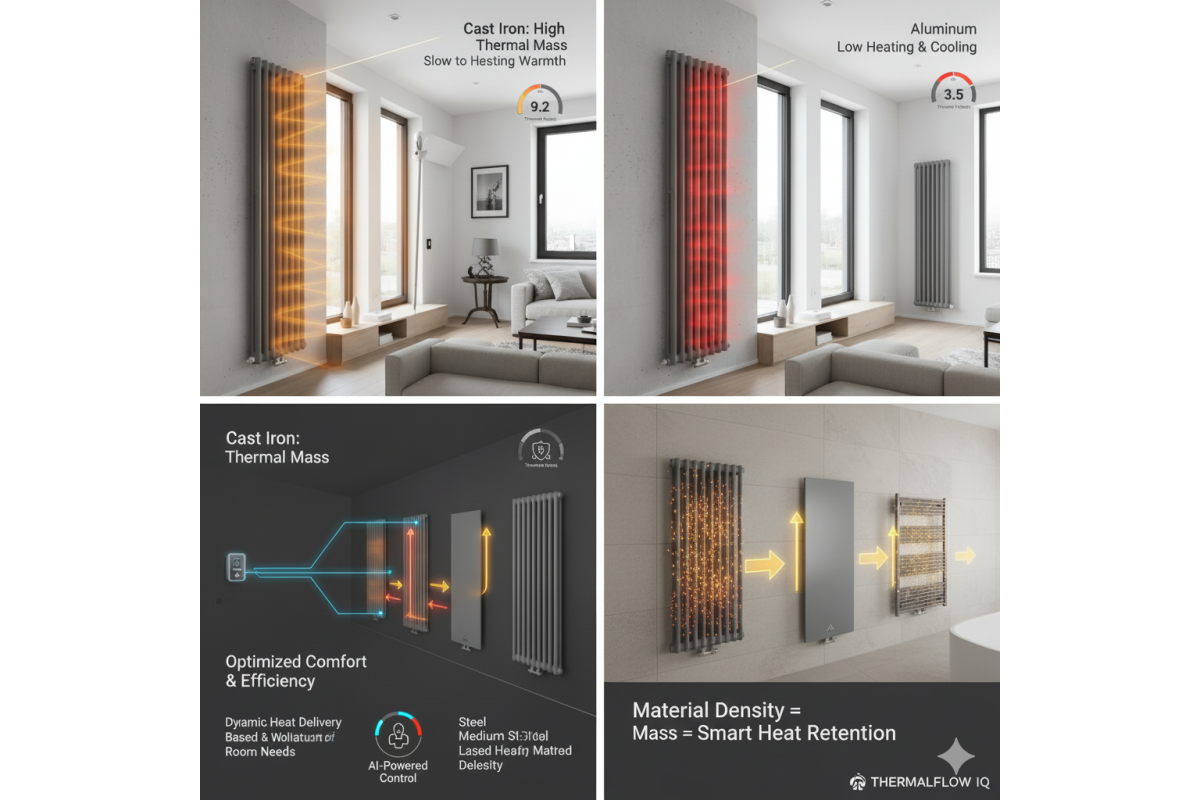

We propose using the Thermal Mass Index to categorize radiators based on their responsiveness. This helps consumers understand how a radiator will behave in the real world, rather than just on a spec sheet.

- TMI Class C (Low Response): Cast Iron. These units take over 30 minutes to reach operating temperature. Once hot, they stay hot for hours, even after you turn the heating off. This makes them impossible to control precisely.

- TMI Class B (Medium Response): Mild Steel. The standard panel radiator found in most UK homes. They are moderately responsive but still hold a significant volume of water and steel mass, leading to sluggish performance.

- TMI Class A (High Response): Aluminium. These units reach effective operating temperature in as little as two minutes. They have low water content (often less than a litre per kW of output) and extremely high thermal diffusivity.

The danger of a "Class C" or low-TMI system in a modern home is the phenomenon of Overshoot. Imagine you set your thermostat to 21°C. Your boiler works hard to get the room to temperature. Once the sensor hits 21°C, it cuts the power. However, your heavy steel or cast iron radiators are essentially hot bricks. They continue to dump heat into the room for another 45 minutes, pushing the temperature up to 23°C or 24°C. That extra heat represents energy you paid for but didn't need, and it often results in a stuffy, uncomfortable room.

The Heat Pump Paradigm: Boosting SCOP

As the UK transitions towards net-zero, many homeowners are installing Air Source Heat Pumps (ASHPs). A common misconception is that you must install underfloor heating to make a heat pump work. This is simply not true. You just need an emitter that is efficient at low temperatures.

Heat pumps operate most efficiently at lower flow temperatures—typically around 40°C to 45°C, compared to the 70°C of a gas boiler. At these lower temperatures, a standard steel radiator struggles to emit enough heat to warm the room. This forces the heat pump to work harder, raising the flow temperature and destroying its efficiency.

Aluminium radiators are the perfect partner for heat pumps. Because aluminium is such a conductive material, it can extract more useful heat from that 45°C water than steel can. Furthermore, the manufacturing process of aluminium radiators (extrusion) allows for fin designs that maximize surface area in a small footprint. Studies suggest that optimizing your radiator circuit for lower flow temperatures can improve a heat pump's Seasonal Coefficient of Performance (SCOP) by up to 20%. That is a direct 20% saving on your electricity bill, purely by choosing the right metal.

Smart Thermostats Need Smart Radiators

Do you use a smart thermostat like Nest, Tado, Hive, or Drayton Wiser? If you do, you are likely utilizing a control algorithm known as TPI (Time Proportional and Integral) control. Unlike old thermostats that simply clicked on and off, TPI thermostats "pulse" your boiler. As the room gets close to the target temperature, the thermostat might fire the boiler for just two minutes, then turn it off for eight.

This "feathering of the gas pedal" is designed to save energy. However, it relies on the radiator responding quickly. If you send a two-minute pulse of hot water into a heavy steel radiator, the steel absorbs the heat, and the pulse ends before the room feels any benefit. The thermostat "thinks" the heating isn't working and eventually forces a longer burn, wasting energy.

An aluminium radiator, with its Class A Thermal Mass Index, responds within seconds. A two-minute pulse results in an immediate wave of warmth into the room. The radiator syncs perfectly with the smart thermostat's brain, allowing for "straight-line" temperature control that holds your room at the perfect temperature without wasteful fluctuations.

Addressing the Corrosion Myth

One barrier that often stops people from upgrading to aluminium is the myth of corrosion. You may have heard that aluminium radiators produce gas or rot from the inside. This is a misunderstanding of basic chemistry that is easily solved.

It is true that if you mix aluminium (the radiator) and copper (the pipes) with untreated water, a chemical reaction can occur. This creates hydrogen gas and can lead to internal pitting. However, this is completely preventable. Every central heating system in the UK requires a chemical inhibitor to be added to the water. When installing aluminium radiators, you simply need to ensure your installer uses a pH-balanced inhibitor (such as Fernox F1 or Sentinel X100). These modern inhibitors create a protective microlayer inside the aluminium, guaranteeing decades of trouble-free service. It is a simple maintenance step that protects your investment.

Design Meets Function: The Vertical Advantage

The benefits of the Thermal Mass Index aren't just technical; they are spatial. Because aluminium is extruded rather than pressed, we can create shapes that steel manufacturers simply cannot. This has led to the rise of the high-output vertical radiator.

In many modern homes, wall space is at a premium. We want open-plan living, large windows, and plenty of furniture, which leaves little room for long, horizontal radiators. Vertical aluminium radiators allow you to utilize the "dead space" on narrow wall pillars. Because of aluminium's incredible efficiency, a narrow vertical column can often output the same amount of heat as a steel radiator twice its width.

For example, ranges like the one pictured above utilize vertical channels that act as convection chimneys. They draw cold air from the floor, heat it rapidly as it passes through the aluminium fins, and project it into the room. This convective power means you can heat a large open-plan kitchen with a unit that takes up less than 300mm of horizontal wall space.

Furthermore, aesthetic choices now align with performance. Textured anthracite finishes, which are incredibly popular in contemporary interior design, actually offer higher thermal emissivity than polished chrome. This means your stylish grey radiator isn't just a design statement; it's a better heater than the traditional alternatives.

Conclusion: The Smart Choice for Modern Living

The radiator market is often viewed as a commodity sector, driven by whoever has the cheapest white panel. But when you look at the Lifetime Cost of Ownership, the cheap steel panel is often the most expensive choice. It forces your boiler to run longer, it wastes energy through overshoot, and it hampers the efficiency of modern heat pumps.

By prioritizing the Thermal Mass Index and choosing aluminium, you are making a strategic investment in your home's infrastructure. You are choosing a material that heats up in minutes, not hours. You are choosing a system that listens to your smart thermostat and responds instantly. You are choosing a future-proof solution that is ready for the low-carbon heating revolution.

The future of heating is not just about being warm; it is about being smart. It is about precision, efficiency, and design working in harmony. It is time to look beyond the BTU and upgrade to the responsive power of aluminium.

.png)

.png)