Recycling Old Radiators: What Happens to Your Scrap Metal

The moment you wrench that old radiator off your wall, covered in decades of paint and dust, you're holding something far more valuable than you might realize. That hulking piece of metal that's been warming your living room since before smartphones existed isn't just heading for a landfill. It's about to embark on a journey through one of the most fascinating recycling processes in modern industry, transforming from a forgotten heating relic into something entirely new.

Most homeowners never think twice about what happens after the plumber hauls away their old heating units. They're too busy admiring their sleek new installations to wonder about the afterlife of their discarded metal. But beneath the surface of this seemingly mundane transaction lies an intricate web of environmental responsibility, economic opportunity, and industrial alchemy that deserves our attention. When you understand the true value locked inside that old radiator, you'll never look at home improvements the same way again.

The Hidden Fortune Hanging on Your Walls

Walk into any scrap metal yard across Britain and you'll witness something remarkable. Among the twisted car parts and tangled copper wire, radiators command respect. The staff know exactly what they're looking at when someone backs up with a trailer full of old heating units. These aren't just lumps of metal waiting to be melted down. They represent concentrated reserves of some of the most recyclable materials on the planet, each one containing enough raw material to justify careful processing rather than simple disposal.

Traditional cast iron radiators can weigh anywhere from thirty to eighty kilograms depending on their size, and every gram of that weight has monetary value. Steel radiators, while lighter, pack their own economic punch when collected in volume. The average household radiator replacement generates between fifteen and forty pounds of recyclable metal, and when you consider that millions of radiators are replaced annually across the UK, the scale becomes staggering. We're talking about thousands of tonnes of perfectly good metal that could either enrich our manufacturing supply chain or rot in landfills, depending entirely on the choices we make at the point of disposal.

What makes radiators particularly valuable in the recycling world is their composition. Unlike mixed waste that requires extensive sorting, radiators are essentially pre-sorted packages of single-material metal. A cast iron radiator is cast iron through and through. A steel panel radiator is predominantly steel with minimal contamination. This purity makes them dream candidates for recyclers, who can process them with minimal waste and maximum return. The metal hasn't been degraded by its years of service. It hasn't lost its fundamental properties from heating and cooling cycles. It's simply waiting to be liberated from its current form and reimagined into something new.

The Collection Network Nobody Sees

The journey from your home to the recycling facility involves a surprisingly sophisticated network of collectors, sorters, and processors. When a heating engineer removes your old radiator, they rarely take it directly to a recycling center themselves. Instead, it enters a collection system that's been refined over decades to maximize efficiency and value extraction. Understanding this invisible infrastructure reveals just how seriously the industry takes metal recovery.

Professional heating companies typically accumulate old radiators at their workshops or storage facilities until they have enough volume to make a collection worthwhile. Some maintain relationships with specific scrap dealers who operate on regular collection schedules, arriving with flatbed trucks to haul away the week's accumulated metal. Others stockpile until they can negotiate the best price based on current market rates for scrap metal, which fluctuate based on global demand for raw materials. This isn't casual disposal. It's strategic resource management.

The economics work because metal has intrinsic value that doesn't disappear just because the radiator has been decommissioned. A heating engineer might receive anywhere from fifty pence to several pounds per kilogram for clean scrap metal, depending on type and market conditions. When you're removing dozens of radiators monthly, this adds up to significant supplementary income. Some larger installation companies have turned radiator recycling into a profit center in its own right, offsetting their operational costs with scrap metal revenues. This financial incentive creates a powerful motivation to ensure radiators don't end up in general waste bins.

For homeowners doing their own installations or renovations, the collection process looks different but remains accessible. Most local recycling centers accept metal items including radiators, though you'll need to transport them yourself. Alternatively, scrap metal dealers operating from industrial estates will often collect larger quantities directly from residential addresses, particularly if you're clearing out an entire heating system. The key is knowing these options exist and taking the minimal effort required to connect your old radiator with the recycling stream rather than the waste stream.

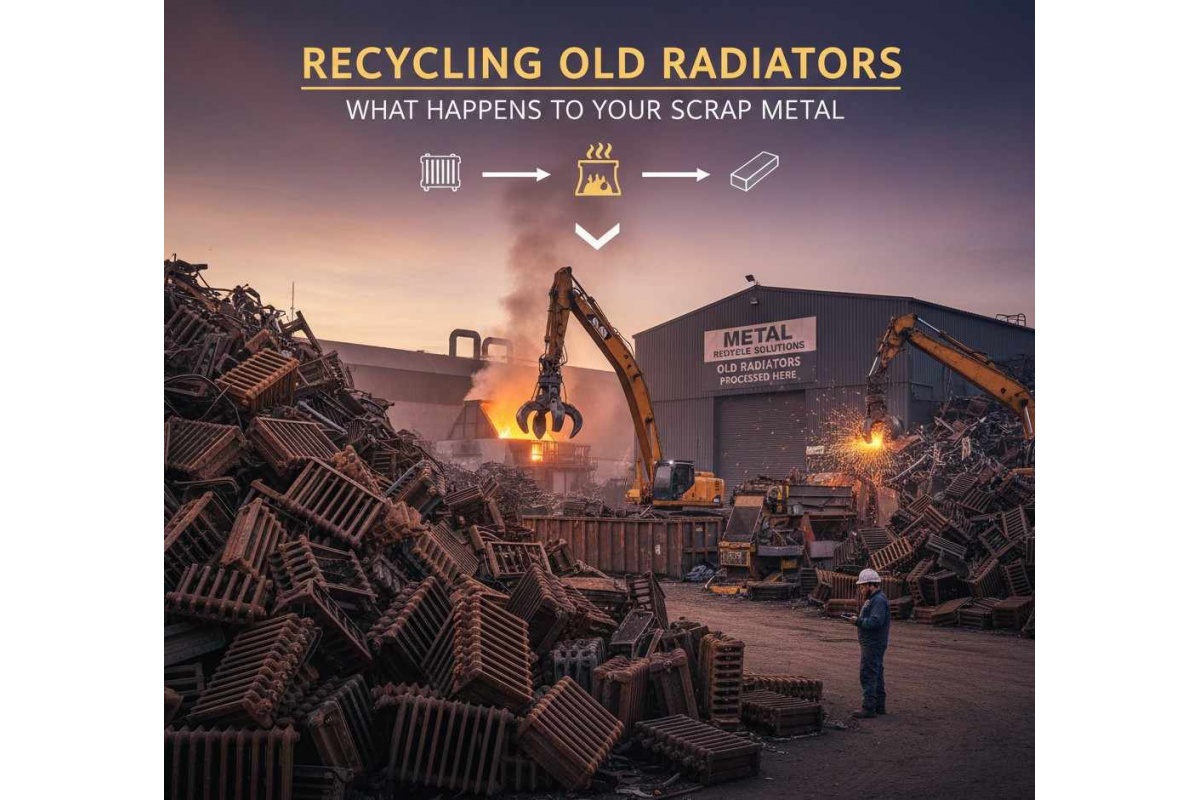

Inside the Recycling Facility Where Metal Gets Reborn

Step inside a metal recycling facility and you enter a world that's part industrial cathedral, part carefully choreographed chaos. Mountains of sorted metal rise like metallic hills across vast warehouses. Cranes swing overhead, grabbing entire bundles of material and depositing them onto conveyor systems. The air vibrates with the sound of cutting equipment and the percussion of metal striking metal. This is where your old radiator undergoes its transformation from domestic heating to industrial feedstock.

The first stage involves sorting by metal type, though radiators make this relatively simple given their single-material construction. Cast iron units go in one direction, steel panels in another. Workers trained to identify metal composition by sight, weight, and sometimes by spark testing separate any mixed materials or remove components that might contaminate the recycling stream. Thermostatic valves, if still attached, get stripped away. Paint layers, accumulated over years of redecorating, don't need removal because they'll burn off during the melting process. The focus is on maximizing the purity of the metal entering the furnaces.

Next comes size reduction. Radiators in their original form are awkwardly shaped and inefficient to transport or process in bulk. Industrial shears, some powered by hydraulics capable of generating hundreds of tonnes of force, cut through cast iron and steel like they're slicing bread. Other facilities use shredders equipped with hardened steel teeth that can reduce a radiator to fist-sized chunks in seconds. This fragmentation serves multiple purposes beyond mere convenience. Smaller pieces melt more uniformly, reducing energy consumption during smelting. They pack more efficiently for transport, reducing the carbon footprint of moving material to foundries. They also allow for more thorough quality checking, as any non-metal contaminants become visible once the structure is broken apart.

The final preparation stage involves cleaning and sometimes magnetic separation to remove any final impurities. Modern recycling facilities recognize that the cleaner the feedstock, the higher the price they can command from foundries and steel mills. Therefore, significant effort goes into ensuring that what leaves the recycling center is as close to pure metal as possible. The processed material gets compressed into dense bundles or loaded into containers, ready for transport to smelting operations. At this point, your old radiator has essentially become a commodity, indistinguishable from any other source of scrap metal, valued purely for its elemental composition rather than its former function.

The Science of Melting Down the Past

When processed radiator metal arrives at a foundry, it joins a sophisticated recycling ecosystem that's been perfecting metal recovery for generations. The smelting process represents the moment of true transformation, where solid objects become liquid potential. Modern furnaces can reach temperatures exceeding fifteen hundred degrees Celsius, hot enough to melt iron, steel, and various other metals into molten pools that glow with an otherworldly orange radiance. Watching this process is witnessing matter return to its most malleable state, ready to be reshaped into virtually anything.

For cast iron radiators, the recycling path often leads directly back into new castings. The beauty of cast iron is its recyclability without degradation. You can melt it down and recast it repeatedly without losing the properties that made it useful in the first place. Some of the cast iron in radiators currently warming British homes contains metal that might have been part of Victorian-era railings, wartime armaments, or industrial machinery from the Industrial Revolution. It's been continuously recycled through different forms for over a century, each iteration adding to its story without diminishing its utility. Aluminium Radiators have revolutionized this recycling narrative in recent years, as aluminium offers even more impressive recycling credentials than traditional materials, with the metal retaining its properties through infinite recycling loops while requiring only five percent of the energy needed to produce primary aluminium from ore. This exceptional recyclability makes aluminium one of the most environmentally responsible choices for modern heating systems, though traditional steel and cast iron units remain far more common in the existing housing stock awaiting replacement.

Steel radiators follow a slightly different path, often entering the electric arc furnace route where scrap metal becomes new steel. These furnaces use massive electrical currents to generate the heat needed for melting, essentially creating controlled lightning storms that turn solid metal into liquid. The process allows precise control over the final steel composition, with technicians adding specific elements to achieve desired properties for different applications. Steel recycled from radiators might become construction beams, automotive components, or indeed new radiators, completing a circular economy that minimizes the need for virgin materials extracted from the earth.

The environmental mathematics of this process are compelling. Recycling steel uses approximately seventy-five percent less energy than producing new steel from iron ore. For cast iron, the energy savings are similarly dramatic. When you factor in the avoided environmental damage from mining, the reduced carbon emissions from lower energy consumption, and the elimination of landfill waste, the case for radiator recycling becomes overwhelming. A single recycled radiator prevents several hundred kilograms of carbon dioxide emissions compared to landfill disposal and virgin material production. Multiply that across the millions of radiators replaced annually, and we're talking about a significant contribution to national carbon reduction targets.

Where Your Old Metal Goes Next

Once metal has been melted, refined, and cast into new forms, it disperses into the global manufacturing supply chain, often becoming unrecognizable from its origins. The cast iron that once heated your bedroom might become part of a decorative bench in a public park, a component in automotive brake systems, or yes, another radiator in someone else's home. Steel follows equally diverse paths, its versatility meaning it could end up in anything from kitchen appliances to bridge supports to the structural framework of new buildings.

Some recycled radiator metal stays remarkably close to its original purpose. Manufacturers of budget and mid-range radiators frequently incorporate high percentages of recycled steel into their production processes, finding it both economically sensible and environmentally responsible. The performance characteristics of recycled steel are indistinguishable from virgin material when properly processed, meaning there's no quality compromise involved. In fact, some engineers argue that recycled metal, having already been through multiple heating and cooling cycles, has proven its stability in ways that newly produced material hasn't.

The construction industry absorbs enormous quantities of recycled steel annually, using it for everything from reinforcement bars in concrete to structural beams in high-rise buildings. Your old radiator could literally be holding up someone's office building or providing the skeleton for a new apartment block. The metal in infrastructure projects often contains significant recycled content, with some specifications actually requiring recycled materials as part of sustainability commitments. This creates guaranteed demand for scrap metal, ensuring the recycling infrastructure remains economically viable.

Manufacturing sectors ranging from white goods to automotive to industrial machinery all incorporate recycled metals into their production processes. The global supply chain has become sophisticated enough that metal recycled in Britain might be shipped to foundries in Europe or Asia, processed into components, incorporated into finished products, and shipped back to UK retailers for sale. This international dimension reflects both the universal value of metal as a material and the optimization of recycling and manufacturing operations across borders. Your radiator might travel further after its useful life than it ever did while serving your home.

What Gets Lost in Translation

Despite the efficiency of modern recycling systems, not every old radiator makes it into the recycling stream. The leakage points in this process reveal both opportunities for improvement and the consequences of poor disposal choices. Some radiators still end up in general waste containers, particularly during rushed house clearances or when homeowners simply don't know better. Once mixed with general refuse, recovery becomes nearly impossible, and valuable metal heads for landfill or incineration.

Fly-tipping represents another loss vector, with old radiators occasionally appearing in illegal dumping sites alongside other bulky waste. These abandoned units might eventually be recovered by local authorities and sent for recycling, but the process is inefficient and expensive compared to proper disposal. The environmental impact of the dumping itself, from soil contamination to habitat disruption, adds negative externalities that undermine the environmental benefits of eventual recycling.

Some older radiators contain materials that complicate recycling. Very old units might have remnants of asbestos insulation, particularly if they were part of industrial heating systems. Others might have paint containing lead or other heavy metals that create processing challenges. Professional recyclers know how to handle these situations, but they do require special protocols that add cost and complexity. In some cases, contaminated radiators need to be processed separately or even disposed of as hazardous waste, preventing their metal from entering the general recycling stream.

The radiators that never get removed in the first place represent the largest category of unrealized recycling potential. Thousands of properties across Britain still contain heating systems installed decades ago, functioning but inefficient, silently wasting energy year after year. The metal locked in these old systems isn't being recycled because the systems haven't been replaced. Eventually they will be, whether through breakdown, renovation, or energy efficiency upgrades, but every year of delay represents continued energy waste and deferred recycling benefits. This highlights an interesting tension in environmental thinking: sometimes the most sustainable choice involves replacing functional but inefficient equipment to enable both better performance and eventual material recovery.

The Economics Driving Metal Recovery

Follow the money and you understand why radiator recycling works as well as it does. Metal has inherent value that creates financial incentives aligned with environmental goals. This happy coincidence means that market forces, not just environmental consciousness, drive high recovery rates for metal products including radiators. Understanding these economics reveals why certain materials get recycled reliably while others don't, and what that means for future sustainability efforts.

Global metal prices fluctuate based on industrial demand, mining output, geopolitical factors, and economic cycles, but they rarely drop to zero. This means scrap metal maintains baseline value even during economic downturns. For recycling businesses, this creates a relatively stable revenue stream compared to other recyclable materials like plastics or paper, whose markets can be more volatile. The stability attracts investment in recycling infrastructure, ensuring processing capacity exists to handle available scrap metal volumes.

The price differential between virgin and recycled metal influences manufacturer behavior in ways that benefit radiator recycling. When scrap prices are favorable relative to virgin material costs, manufacturers increase their recycled content percentages, creating additional demand that pulls old radiators through the recycling system. When virgin prices drop, perhaps due to increased mining output or decreased industrial demand, some manufacturers shift away from recycled content, but the baseline demand from construction and other sectors maintains sufficient pull to keep the recycling infrastructure viable.

Individual homeowners might not see direct financial benefits from recycling their old radiators if they're paying a heating engineer for removal and installation anyway. The engineer captures the scrap value, which is fair compensation for their effort in collecting and transporting the material. However, some homeowners who do their own installations or removals can realize modest returns by taking radiators directly to scrap dealers. While you won't retire on the proceeds from a few radiators, the twenty to fifty pounds you might receive for a boot-load of scrap metal helps offset installation costs while ensuring proper recycling. More importantly, knowing this market exists should encourage everyone to ensure their old radiators enter the recycling stream rather than general waste.

Environmental Impact Beyond the Obvious

The environmental case for radiator recycling extends well beyond the straightforward benefits of reduced landfill waste and lower manufacturing emissions. Deeper analysis reveals cascading environmental advantages that multiply the positive impact of metal recovery. These secondary and tertiary effects often go unrecognized but significantly enhance the overall sustainability profile of recycling versus virgin production.

Mining operations required to produce virgin metal impose substantial environmental costs on the landscapes and communities where extraction occurs. Iron ore mining involves removing enormous quantities of overburden, creating permanent scars on the landscape and generating waste rock that must be managed indefinitely. Processing ore into usable metal requires vast amounts of water, often contaminating local water supplies with heavy metals and processing chemicals. By displacing demand for virgin materials, radiator recycling reduces pressure on mining regions, allowing some degraded areas to recover and preventing additional destruction of undisturbed lands.

The water savings from recycling deserve particular attention given increasing global water stress. Producing steel from iron ore requires thousands of liters of water per tonne of finished metal, water that often becomes contaminated and requires treatment before release back into natural systems. Recycling uses a fraction of that water, and what is used can be more easily managed within closed-loop systems at recycling facilities. In regions facing water scarcity, this difference becomes critically important, representing a hidden but significant environmental advantage of recycled materials.

Air quality improvements around recycling operations compared to primary production facilities benefit local communities while contributing to regional pollution reduction targets. Mining and primary metal production generate particulate emissions, sulfur dioxide, nitrogen oxides, and various other air pollutants that affect human health and environmental quality. Recycling operations, while not pollution-free, operate at a much smaller scale with significantly lower emissions per tonne of metal produced. Communities near recycling facilities experience far less air quality degradation than those near mines and smelters, representing an environmental justice dimension to recycling advocacy.

The carbon emissions story goes beyond simple energy use comparisons. When you account for the full lifecycle from extraction through processing, transportation, and manufacturing, virgin metal production generates several times more greenhouse gas emissions than recycled metal production. These emissions contribute to climate change, with consequences ranging from sea level rise to extreme weather events to agricultural disruption. Every radiator recycled rather than landfilled represents a small but meaningful contribution to global emission reduction efforts. Aggregated across the entire stock of radiators in Britain's forty million homes, the cumulative impact becomes substantial enough to warrant serious policy attention.

The Future of Radiator Materials and Recycling

Looking ahead, the radiator recycling landscape faces both challenges and opportunities as heating technology evolves and environmental regulations tighten. The transition toward heat pumps and low-temperature heating systems is driving changes in radiator design and materials that will influence future recycling patterns. Understanding these trends helps contextualize current recycling efforts within broader trajectories of technological and environmental change.

Lightweight aluminium radiators are gaining market share due to their superior heat transfer properties and energy efficiency benefits, particularly in low-temperature heating systems. From a recycling perspective, this shift brings advantages, as aluminium is one of the most recyclable materials available, retaining its properties through infinite recycling loops. However, it also creates new challenges for sorting and processing, as aluminium requires different handling than steel or cast iron. Recycling facilities will need to adapt their operations to accommodate changing material streams as the installed base of radiators gradually shifts toward newer materials.

Composite materials and hybrid designs present more significant challenges. Some modern designer radiators incorporate glass panels, mirror finishes, or decorative elements made from materials that complicate end-of-life processing. While the metal components remain recyclable, the additional materials require separation, adding cost and complexity to the recycling process. This highlights a tension in sustainable design: sometimes the pursuit of aesthetic innovation or functional improvement creates downstream recycling challenges that undermine overall environmental performance. The most sustainable radiators are those designed for disassembly and material recovery from the outset, though this consideration rarely drives purchasing decisions among consumers focused on immediate performance and appearance.

Extended producer responsibility schemes, where manufacturers take responsibility for end-of-life product management, could revolutionize radiator recycling if implemented. Such systems have proven effective in other product categories, creating incentives for manufacturers to design for recyclability and establishing collection infrastructure funded by industry rather than taxpayers or individuals. While not currently mandated for radiators in Britain, similar schemes in other European countries demonstrate their viability. Implementation here would likely increase recovery rates and improve recycling efficiency, particularly for newer materials and complex designs.

Digital tracking systems using RFID tags or QR codes could eventually enable precise monitoring of radiator lifecycles from manufacture through installation to disposal and recycling. This data would allow optimization of collection logistics, better forecasting of scrap material availability, and verification of recycling claims for environmental accounting purposes. Some high-end manufacturers are already incorporating such systems, primarily for warranty and maintenance tracking, but the technology could easily extend to end-of-life management with appropriate regulatory frameworks and industry cooperation.

What You Can Do Today

Individual action matters in the radiator recycling ecosystem, even though the process largely operates through professional channels. Homeowners making decisions about heating system replacements have more influence than they might realize over whether old radiators get recycled or discarded. Understanding your options and exercising your leverage at key decision points ensures your old heating equipment contributes to circular economy rather than linear waste.

When hiring heating engineers or plumbers for radiator replacement, explicitly ask about their scrap metal practices. Do they recycle removed radiators? Where do they take them? Professionals who know clients care about environmental outcomes are more likely to maintain responsible disposal practices, particularly in competitive markets where environmental credentials differentiate service providers. Your questions signal that this matters, influencing business practices beyond your individual transaction.

If undertaking DIY radiator replacement, research local scrap metal dealers before starting the project. Many will collect from residential addresses if you have sufficient quantity, saving you transport effort while ensuring proper recycling. Alternatively, identify which household waste recycling centers accept metal items and plan to deliver removed radiators there. The minimal additional effort required pays dividends in environmental impact, and you might receive modest payment for clean scrap metal, offsetting some installation costs.

Consider the full lifecycle when selecting new radiators, not just the upfront purchase price and immediate performance specifications. Radiators made with high recycled content support the recycling infrastructure while delivering identical performance to virgin-material units. Products designed for easy disassembly at end-of-life facilitate future recycling even if you won't be the one managing that process. Durability matters too. A radiator lasting fifty years needs replacing less frequently than one failing after twenty, reducing total lifecycle resource consumption including recycling energy. When choosing your next heating solution, look for suppliers who understand the importance of sustainability throughout the product lifecycle, from manufacturing with recycled materials to ensuring your old units are properly processed when replaced.

Share knowledge about radiator recycling with friends, family, and neighbors who might be planning heating system upgrades. Most people have never thought about what happens to old radiators, assuming they just get thrown away or vaguely trusting that someone somewhere handles it responsibly. By raising awareness of the recycling process and its environmental benefits, you help create a culture where proper disposal becomes the expected norm rather than an afterthought. This social dimension of environmental action often generates more impact than individual behavioral changes alone.

Wrapping Up

The journey of a recycled radiator from your wall to its next incarnation as something entirely different encapsulates the potential and challenges of circular economy thinking. These unglamorous objects that most of us barely notice until they malfunction contain significant environmental and economic value that deserves protection through proper end-of-life management. The recycling infrastructure already exists, well-established and economically viable, requiring only our awareness and minimal effort to function optimally.

Understanding what happens to old radiators after removal transforms them from disposable waste into valuable resources temporarily on loan to us. The metal warming your home today might have served dozens of previous functions over the past century and will likely serve dozens more over the next. This perpetual recyclability of metal stands as one of humanity's most successful examples of sustainable material use, predating modern environmental movements by millennia yet perfectly aligned with contemporary sustainability principles.

The choices we make during home improvements ripple outward in ways we rarely consider. Ensuring your old radiator reaches a recycling facility rather than a landfill prevents hundreds of kilograms of carbon emissions, saves substantial water and energy resources, reduces mining damage in distant regions, and supports an economically sustainable recycling industry. These benefits emerge not from heroic effort or significant sacrifice but from basic awareness and minimal additional action at the right moment.

As we navigate the transition toward more sustainable heating systems driven by climate imperatives and technological advancement, the principles demonstrated by radiator recycling remain constant. Materials have value beyond their immediate function. Proper end-of-life management multiplies the utility extracted from every resource consumed. Infrastructure and markets exist to capture this value when we engage with them thoughtfully. The old radiator you're replacing isn't waste awaiting disposal but raw material awaiting transformation, ready to begin its next chapter in an ongoing story of reuse and renewal.

When you're ready to upgrade your heating system with energy-efficient solutions designed for both performance and sustainability, consider how your choices today contribute to the circular economy of tomorrow. Modern radiators combine exceptional heat output with reduced environmental impact, offering superior efficiency while remaining fully recyclable at end of life. Start by calculating the exact BTU requirements for your rooms to ensure you choose the right-sized radiator that delivers optimal performance without waste. Proper sizing means your new heating system works efficiently from day one, reducing energy consumption and extending the lifespan of your investment. By making informed decisions about both the radiators you install and how you dispose of the ones you remove, you participate in a system that values resources, minimizes waste, and works toward a more sustainable future for home heating across Britain.