Oscar Sections, End Panels and Accessories Products

Frequently Asked Questions

What is the technical difference between the Oscar Optional End Panels and the Oscar Optional Sections when building a custom radiator size?

The Oscar End Panels and Optional Sections serve distinct structural functions. The End Panels are sold as a pair and are designed to form the outer boundaries of the radiator; they often feature the integral feet or side finishes required for a complete look. The Optional Sections are intermediate blocks, each 80mm wide, which are added between the end panels to increase the overall width and heat output. You cannot build a functioning radiator using only intermediate sections; you must technically anchor them with the correct End Panel kit to ensure stability and watertight integrity.

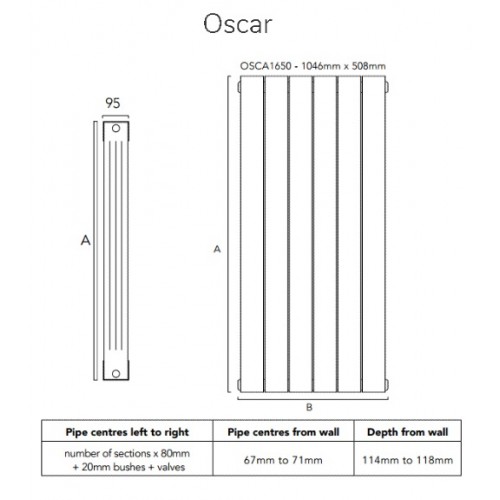

How do I calculate the total width of my assembled Oscar Aluminium Radiator using the section dimensions provided on this page?

To calculate the precise technical width of your assembly, you must account for both the intermediate sections and the end panels. Each intermediate Oscar Optional Section adds exactly 80mm to the length. The End Panels have a specific width of 95mm. Therefore, the formula for total width is: (Number of Intermediate Sections

Can I install the Oscar Optional Towel Bar on any height of Oscar Radiator or are there technical restrictions?

The Oscar Optional Towel Bar (480mm) is designed to clamp onto the vertical columns of the radiator. While it is technically compatible with the Oscar range, it is most practical on the taller vertical models (e.g., 1646mm, 1846mm, 2046mm) where it sits at a convenient height for hanging towels without obstructing the main heat emission zone near the floor. You must ensure that the radiator has enough vertical clearance and that the bar is tightened sufficiently to prevent slipping, as the aluminium surface is smooth.

What mechanism is used to join the Oscar Optional Sections together if I want to extend the radiator width on-site?

The Oscar sections are joined using specific joining nipples and gaskets. These nipples feature opposing threads (one end left-hand thread, one end right-hand thread). When turned with a specific joining tool or key, the nipple pulls the two aluminium sections together, compressing the gasket to form a watertight seal. This technical assembly method allows you to extend the radiator to virtually any width, provided you have the correct torque tool to ensure the joints do not leak under high system pressure.

Are the Oscar End Panels and Sections available in custom finishes to match specific interior design schemes?

Yes, while the standard stock finish is RAL 9010 White, both the End Panels and Optional Sections are available in a wide range of custom finishes. You can select from the RAL Colour chart or Special Finishes (such as textured or metallic effects). From a technical production standpoint, these custom finishes are applied as a high-durability powder coat. It is critical to order all sections and panels at the same time to ensure the dye lot matches perfectly, as slight variations can occur between different production batches.

How does adding more Oscar Optional Sections affect the total BTU and Wattage output of the heating unit?

The heat output of the Oscar radiator scales linearly. Each Optional Section has a specific rated output (e.g., an 1846mm high section provides 1013 BTUs at Delta T50). To solve the heating requirement for a large room, you simply add the BTU values of all the intermediate sections plus the end panels together. This modular technical characteristic allows you to precisely engineer the radiator to match the heat loss calculation of your room, preventing the common problem of undersizing or oversizing the emitter.

What is the advantage of using Oscar Aluminium Sections over Cast Iron sections for a tall vertical installation?

The primary technical advantage is the weight-to-heat ratio. Oscar Aluminium Sections are significantly lighter than cast iron equivalents. An 1846mm high cast iron section is extremely heavy and difficult to maneuver, often requiring specialist lifting equipment and reinforced floors. The Oscar aluminium sections can be handled much more easily by a standard installer. This solves the problem of installing large, high-output vertical radiators in upper-story rooms or on floors where structural weight limits are a concern, without sacrificing the traditional aesthetic.

Do I need to purchase a separate joining kit or accessories when buying replacement End Panels?

Generally, if you are buying Replacement End Panels to repair an existing unit, you may need new gaskets and potentially new nipples if the old ones are seized or damaged during disassembly. The End Panels themselves are structural components. If you are building a new radiator from scratch using these parts, you must ensure you have the correct number of joining nipples (two per joint) and gaskets. It is technically advisable to replace gaskets every time a section is separated to guarantee the 10-year warranty remains valid against leaks.

How does the sectional nature of the Oscar radiator help in solving access problems during installation in tight spaces?

One of the biggest problems with large welded radiators is physically getting them into the room, especially up narrow staircases or around tight corners. The Oscar Sectional design solves this technical logistics issue completely. You can transport the radiator in smaller, manageable blocks (e.g., carrying the End Panels and Sections separately) and then assemble them in the room of installation. This allows for the creation of massive, high-output radiators in locations that would be inaccessible to a pre-welded steel panel radiator of the same size.

Why is it important to use a rust inhibitor compatible with aluminium when assembling and filling the Oscar radiator sections?

Aluminium is technically susceptible to electrolytic corrosion if the pH of the heating water is incorrect. When assembling Oscar sections, you are creating a mixed-metal environment (aluminium radiator, copper pipes, brass valves). You must use a high-quality central heating inhibitor specifically formulated for mixed-metal systems and maintain a neutral pH (around 7-8). Failure to do this can lead to hydrogen gas build-up and internal pitting of the aluminium sections, which is a common problem that leads to pinhole leaks and voids the manufacturer's guarantee.