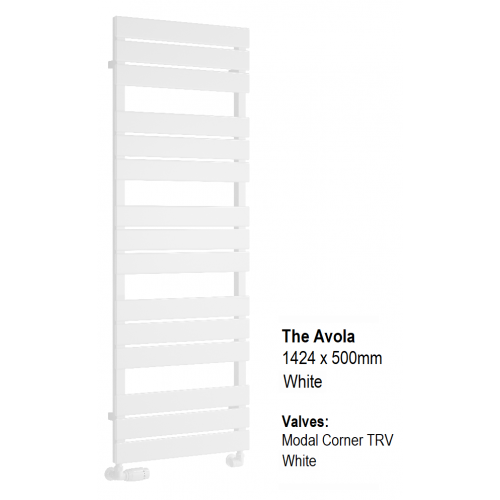

The Avola Products

Showing 1 to 3 of 3 (1 Pages)

Frequently Asked Questions

How do I determine if the Avola Designer Towel Rail provides sufficient heat output for my specific bathroom dimensions?

To ensure your bathroom is adequately heated you must compare the BTU output of the Avola model against your room requirement. The Avola range offers varying outputs: the 823mm height delivers 1367 BTUs, the 1124mm delivers 1849 BTUs, and the 1424mm delivers 2311 BTUs at Delta T50. You should use a BTU calculator to measure your room volume and insulation factors. If the calculated requirement exceeds the Avola output, we recommend using this rail primarily for towel warming and supplementing the room temperature with an additional radiator or underfloor heating.

What specific components are required to convert the Avola radiator into a dual fuel system for summer use?

Converting the Avola to dual fuel requires specific technical components to allow operation via both the central heating boiler and mains electricity. You will need a compatible T-piece to split the inlet connection, a heating element that matches the wattage rating of the specific Avola size (401W, 542W, or 678W), and a set of radiator valves. This setup allows you to isolate the radiator from the central heating system during summer and activate the electric element to dry towels without heating the entire house.

How does the 87mm depth of the Avola affect installation in narrow alcoves or behind doors?

The Avola features a compact projection which makes it an ideal space saving solution. The fixed depth of 87mm from the wall to the front face means it intrudes minimally into the room. When planning installation in a narrow alcove or behind a bathroom door you must measure the available clearance to ensure the door can fully open without striking the radiator. This slim vertical profile is engineered specifically to maximize floor space in smaller en-suites while maintaining high heat efficiency.

Can the Avola be installed on any pipework system and what are the valve connection standards?

The Avola utilizes standard 1/2 inch BSP connections which are compatible with the vast majority of UK central heating pipework. The inlet points are located at the bottom of the vertical uprights. If your pipes emerge from the floor you will require straight valves. If your pipes run along the wall you will require angled or corner valves. Ensure your plumber measures the pipe centers accurately (width of rail plus valve allowance) before first fix to avoid modifying pipework later.

What is the difference between Delta T50 and Delta T60 ratings when reading the Avola technical specifications?

The heat output listed for the Avola (e.g., 2311 BTUs for the largest model) is calculated at Delta T50 which is the European standard difference between the radiator temperature and room temperature. If your system operates at older Delta T60 standards the actual output will be higher than listed. Conversely, if you have a low temperature system like a heat pump operating at Delta T30 or T40 the effective heat output will be lower. You must adjust your sizing calculations based on your boiler supply temperature to ensure the room stays warm.

Does the chosen finish (Anthracite, Black, or White) impact the thermal retention or heat emission of the rail?

While different finishes can technically have marginal differences in emissivity, the Avola range is engineered to perform efficiently across all options. The Anthracite, Black, and White finishes are high quality powder coats designed to facilitate excellent heat transfer while resisting corrosion in humid environments. You can select the finish based on your design preference for a modern statement piece without worrying about a significant drop in thermal performance compared to chrome alternatives.

How do I troubleshoot cold spots at the top of my Avola vertical radiator after installation?

Cold spots at the very top of vertical rails like the Avola usually indicate trapped air within the system rather than a product fault. This prevents hot water from circulating to the highest point. To solve this you need to locate the bleed valve at the top of the unit. With the heating system turned off and cool, use a radiator key to slightly open the valve until the hissing air stops and water begins to flow. Close the valve immediately and check your boiler pressure to ensure it remains at the correct operating level.

What are the electrical zone safety requirements for installing the Avola as an electric or dual fuel unit?

When installing the Avola with an electric element for dual fuel capability you must adhere to IP rating zones in the bathroom. If the unit is placed within Zone 2 (0.6m from the bath or shower) the electric element must be IPX4 rated or higher. The fused spur connecting the element to the mains electricity should be located outside the bathroom or in a safe zone. All electrical work for dual fuel modifications must be carried out by a qualified electrician to comply with UK building regulations.

How many horizontal sections does each Avola size have and how does this affect towel storage capacity?

The structural design of the Avola varies by height to optimize both heat surface area and towel hanging space. The 823mm model has 9 sections, the 1124mm model has 12 sections, and the 1424mm model has 15 sections. From a problem solving perspective, if you have a large family requiring multiple towels to be dried simultaneously, you should opt for the 1424mm model not just for the higher BTU output but for the increased number of bars which improves air circulation between damp towels.

What does the 10 Year Guarantee cover regarding the structural integrity and finish of the Avola?

The 10 Year Guarantee provided with the Avola protects you against manufacturing defects such as leaks caused by poor welding, material failure, or flaking of the powder coated finish under normal usage conditions. It ensures that the carbon steel construction maintains its integrity over time. However, it does not cover damage caused by improper installation, the use of corrosive cleaning agents on the finish, or internal corrosion caused by a central heating system that has not been treated with the correct inhibitor chemicals.