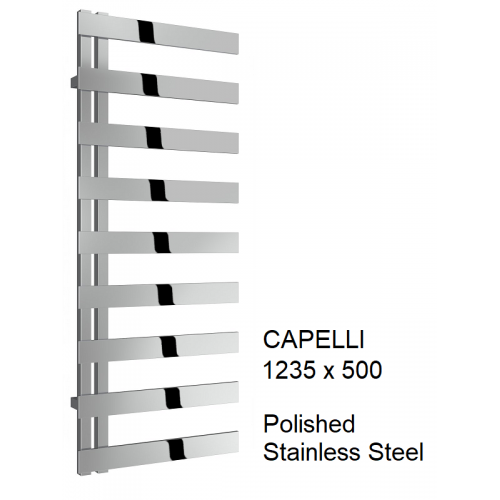

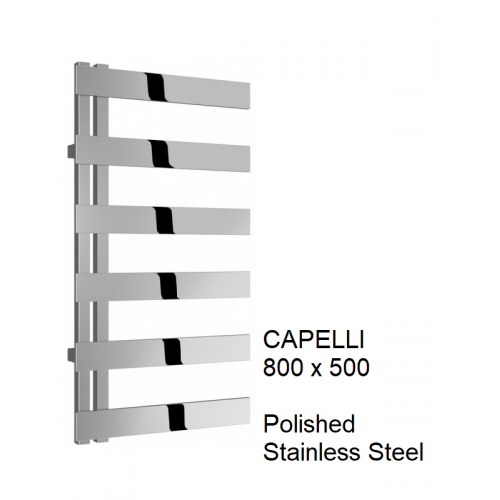

The Capelli Products

Showing 1 to 3 of 3 (1 Pages)

Frequently Asked Questions

How does the rectangular bar design of The Capelli influence heat transfer efficiency compared to round tubes?

The Capelli utilizes flat rectangular crossbars and square collectors which technically offer a different surface area to volume ratio than standard round tubes. This geometric shape provides a broader contact surface for towels, which facilitates faster drying through direct conduction. Additionally, the flat surfaces can assist in radiating heat more evenly into the room, maximizing the thermal efficiency of the stainless steel material.

What is the correct method to calculate if the BTU output is sufficient for a specific bathroom volume?

To ensure The Capelli heats your room effectively, you must calculate the heat loss of the space rather than just guessing. This involves measuring the height, width, and length of the bathroom to get the volume and adjusting for factors like single glazing or external walls. You should then compare this figure against the listed output at Delta T 50C (e.g., 1942 BTUs for the 1525mm model). If the rail output is lower than the room requirement, a secondary heat source may be needed.

Why is AISI 304 stainless steel recommended for wet environments over standard mild steel?

AISI 304 stainless steel is an alloy containing specific percentages of chromium and nickel which react with oxygen to form a microscopic, self-repairing passive layer on the surface. Unlike mild steel which relies on chrome plating to stop rust, stainless steel is corrosion resistant all the way through. This prevents the common issue of surface peeling or rusting in high-humidity bathroom environments, ensuring structural integrity for many years.

What are the technical requirements for converting this central heating rail to dual fuel operation?

Converting The Capelli to dual fuel requires the installation of an electric heating element and a T-piece adapter at the valve inlet. This allows the rail to be heated by the central boiler in winter and by electricity in summer. It is critical to select an element with a wattage that is safely below the maximum liquid capacity of the rail to prevent internal pressure buildup, and the electrical connection must be fused and compliant with bathroom safety zones.

How does the 105mm wall projection affect pipework roughing in and installation planning?

The 105mm depth represents the distance from the wall to the front face of the towel rail. For the installation of pipework, the pipe centers (where the pipes come out of the floor or wall) will be positioned approximately 65mm to 85mm from the wall, depending on the bracket adjustment. Installers must adhere to these measurements to ensure the radiator valves align vertically without putting stress on the valve unions or the rail connections.

What type of maintenance is required to protect the polished finish from surface damage?

Although the polished finish looks like chrome, it is actually the raw stainless steel buffed to a high shine. To maintain this, you must avoid using steel wool, chlorides, or bleach-based cleaners, as these can disrupt the protective oxide layer and cause tea-staining. The correct technical maintenance involves simple wiping with a soft microfiber cloth and warm water to remove mineral deposits and dust without scratching the surface.

Does The Capelli require specific radiator valves for connection to the central heating system?

The Capelli has standard half inch BSP bottom connections, making it compatible with all standard 15mm radiator valves. The choice of valve type depends on your pipe direction. If pipes emerge from the floor, you require straight valves. If pipes emerge from the wall, you require angled or corner valves. Thermostatic valves are recommended to control the flow rate and temperature output of the rail automatically.

How should air locks be resolved if the top bars of the towel rail remain cold?

If the top section of The Capelli remains cold while the bottom is hot, it indicates trapped air preventing the hot water from circulating to the top. To resolve this technical issue, you must open the bleed valve located at the top of the collector using a radiator key while the pump is off. Allow the air to hiss out until a steady stream of water appears, then close the valve to restore full hydraulic pressure and heat distribution.

Is this stainless steel rail compatible with both open vented and sealed heating systems?

Yes, the stainless steel construction and welding quality of The Capelli make it robust enough to handle the operating pressures of both traditional open vented systems (fed by a tank) and modern sealed systems (combi boilers). It is pressure tested during manufacturing to ensure it can withstand standard domestic heating fluctuations without leaking or deforming.

What does the 10 year guarantee cover regarding manufacturing and material defects?

The 10 year guarantee explicitly covers faults arising from the manufacturing process, such as imperfect welds or material failure like porosity in the steel. Since the material is solid stainless steel, the warranty assures the user that the unit will not develop pinhole leaks due to internal corrosion under normal water chemistry conditions. It guarantees the unit remains water-tight and visually consistent for the decade.