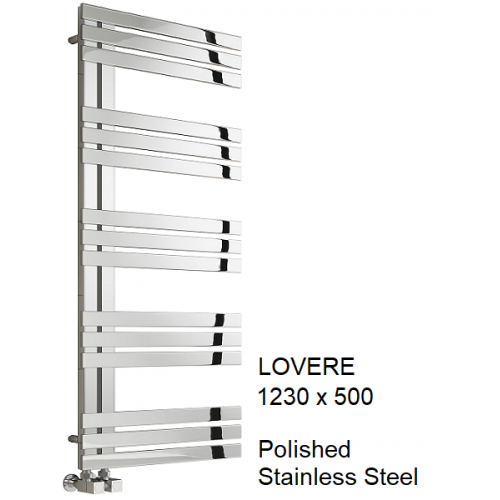

The Lovere Products

Showing 1 to 3 of 3 (1 Pages)

Frequently Asked Questions

How does the high grade stainless steel construction of the Reina Luna technically prevent corrosion in wet rooms?

The Reina Luna is manufactured from high-grade stainless steel, which contains a specific alloy of chromium and nickel. Unlike chrome-plated mild steel radiators that rely on a thin surface coating, the stainless steel material itself is inherently resistant to oxidation. Technically, this allows the metal to form a passive oxide layer that self-repairs if scratched, providing a permanent solution to rust and "tea-staining" issues commonly found in high-humidity environments like wet rooms or shower areas, ensuring the rail maintains its structural integrity for decades.

What are the precise pipe center measurements required for first fix plumbing of the Reina Luna?

For accurate roughing-in of pipework, you must calculate the pipe centers based on the specific width of the Reina Luna model you select. The technical rule is the Radiator Width minus 32mm. For example, on the 500mm wide model, the pipe centers are 468mm. The distance from the wall to the pipe center is adjustable between 50mm and 60mm depending on the bracket depth setting. Installing pipes to these specific coordinates solves the problem of misaligned valves and prevents stress on the connection threads during final installation.

Can the Reina Luna Towel Rail be converted to a dual fuel system for year round operation?

Yes, the Reina Luna is fully compatible with dual fuel conversion. To solve the problem of damp towels in summer when the central heating is off, you can install a "T-Piece" connector on one of the bottom inlets. This allows you to insert an electric heating element into the vertical collector while keeping the central heating valves connected to the side of the T-Piece. You must ensuring the element's wattage does not exceed the rail's liquid capacity to prevent overheating and pressure buildup.

Why does the polished finish of the Reina Luna offer superior thermal performance compared to chrome plated rails?

Chrome plating acts as a thermal insulator, trapping a percentage of the heat inside the metal core. The Reina Luna features a polished stainless steel finish, which is the raw material buffed to a shine rather than a plated coating. Technically, this results in higher thermal emissivity, allowing heat to transfer more efficiently from the internal water to the bathroom air. For instance, the 1200mm x 500mm model delivers approximately 1717 BTUs (Delta T50), providing a more effective heating solution than an equivalent chrome-plated mild steel rail.

What does the 25 Year Manufacturer Guarantee technically cover for the Reina Luna range?

The 25 Year Guarantee provided with the Reina Luna verifies the superior durability of the stainless steel material. It technically covers you against manufacturing defects such as leaks in the welds, material failure, and internal corrosion under normal operating conditions. This long-term warranty solves the financial risk of premature replacement, confirming that the product is manufactured to BS EN 442 standards and has been pressure-tested to withstand standard central heating operating pressures without structural failure.

Is the Reina Luna suitable for installation on a direct hot water system (DHW)?

Unlike mild steel radiators which will rust if connected to fresh water, the stainless steel construction of the Reina Luna makes it technically suitable for open or direct hot water systems (where the water comes directly from the hot water cylinder rather than a closed heating loop). This solves the problem for homes without a standard central heating loop, allowing the rail to be plumbed into the domestic hot water circuit, provided the water composition is not excessively acidic or high in chlorides.

How do the 22mm horizontal tubes of the Reina Luna affect the towel drying efficiency?

The Reina Luna features 22mm diameter horizontal cross tubes arranged in a flat ladder design. This tube diameter is technically optimized to provide a sufficient surface area for heat transfer without being too bulky. The spacing between the tube groups allows for multiple thick bath sheets to be hung simultaneously without overlapping excessively. This solves the airflow problem seen in denser rails, ensuring warm air circulates through the fabric fibers to dry towels rapidly and reduce bacterial growth.

What type of valves are required to connect the Reina Luna to standard 15mm copper pipework?

The Reina Luna uses standard 1/2 inch BSP female connections located at the bottom of the vertical collectors. To ensure correct flow dynamics, your valve choice depends on your pipe position. If your pipes emerge from the wall, you technically require Angled Valves to create a 90-degree turn into the rail. If your pipes come up from the floor, Straight Valves are the correct choice. Using the correct valve orientation prevents flow restriction and eliminates the noise ("water hammer") associated with forcing water through tight bends.

Does the Reina Luna require a specific type of wall fixing for safe installation?

The Reina Luna is supplied with four adjustable wall brackets. However, stainless steel is denser and heavier than mild steel. To technically solve the stability issue on partition or plasterboard walls, you must ensure the fixings are anchored into the timber studs or use heavy-duty hollow wall anchors (like toggle bolts). Relying on standard rawl plugs in drywall is unsafe for a fully loaded rail. The adjustable brackets allow you to set the wall distance between 65mm and 75mm, helping to accommodate uneven tile surfaces.

How do I bleed air from the Reina Luna if the top bars are not heating up?

If the top section of your Reina Luna rail feels cold while the bottom is hot, it indicates an air lock in the system. To fix this technical issue, turn off your central heating pump to stop water circulation. Locate the air vent (bleed valve) at the top of the vertical collector. Use a radiator key or a flat-head screwdriver to open the valve slightly until the hissing sound stops and water begins to trickle out. This displaces the trapped air with hot system water, restoring full thermal efficiency to the upper rails.