Controllable Immersion Elements Products

Showing 1 to 4 of 4 (1 Pages)

Frequently Asked Questions

How does a controllable immersion element differ technically from a standard single speed heater?

A standard immersion heater operates on a binary on or off basis, consuming full power until the thermostat cuts it off. A controllable immersion element, such as the Thermostatic Element MEG-1.0, utilizes advanced microprocessors to regulate the resistance heating coils. This allows the device to modulate power output, maintain a precise liquid temperature within the radiator or cylinder, and significantly reduce energy consumption by preventing temperature overshooting and cycling on and off less frequently.

How do I determine if a controllable immersion element is compatible with my existing hot water cylinder or radiator connection?

To ensure compatibility, you must verify the threaded entry size of your vessel. Most UK hot water cylinders and radiators utilize a British Standard Pipe or BSP thread. The two standard sizes are 1.25 inch and 2.25 inch BSP. You should measure the diameter of the boss on your cylinder or radiator before purchasing. The specifications on the Budget Radiators product page list the thread size for each element, ensuring you can match the element directly to your specific hardware requirements.

What are the technical advantages of using a Weekly Thermostatic Element for energy cost management?

The Weekly Thermostatic Element allows for 7 day programming, meaning you can set specific heating intervals for every day of the week. Technically, this prevents the element from drawing electrical current when the room is unoccupied. By aligning the heating schedule with your specific usage patterns or off peak electricity tariffs, you minimize wasted kilowatt hours. The internal memory of the unit retains these settings, ensuring that the heating cycle remains automated and efficient without daily manual input.

Can I install the Touch Control Element on a standard central heating towel rail to create a dual fuel system?

Yes, these elements are ideal for creating a dual fuel towel rail. This setup requires a T-piece adapter which allows both the electric element and the central heating valve to be connected to the same inlet. Technically, this setup allows you to heat the rail via the boiler in winter and use the electric Touch Control Element in summer when the central heating is turned off. You must ensure the element wattage does not exceed the maximum thermal output of the rail to prevent internal pressure buildup.

How does the freeze protection function work on the MEG-1.0 thermostatic element?

The freeze protection mode is a safety feature embedded in the microprocessor of the MEG-1.0 element. When the unit is in standby mode, the internal temperature sensor continuously monitors the fluid temperature inside the radiator. If the temperature drops below a critical threshold, typically around 5 to 7 degrees Celsius, the element automatically activates a low power heating cycle. This prevents the water or glycol fluid inside from freezing and expanding, which could otherwise rupture the radiator seals or the metal body itself.

What is the correct method for calculating the required wattage when selecting an electric heating element?

Calculating the correct wattage involves matching the element output to the thermal capacity of the radiator. You should check the Delta T50 or Delta T60 BTU rating of your radiator and convert that to Watts (divide BTU by 3.41). It is technically advisable to select an element that provides roughly 90 to 95 percent of the radiator manufacturer stated wattage capacity. If you choose an element with a higher wattage than the radiator can handle, the fluid may boil, causing the pressure relief valve to open or the element to overheat and fail prematurely.

Why is the Incoloy or stainless steel construction mentioned in the product specifications important for hard water areas?

In hard water areas, calcium and magnesium minerals precipitate out of the water when heated, forming limescale on the heating element. A standard copper sheath can corrode or overheat quickly under these conditions. Elements made from high grade stainless steel or Incoloy alloys have a much higher resistance to corrosion and scale adhesion. This superior material construction ensures efficient heat transfer is maintained over the long term and extends the lifespan of the unit, which is supported by the 10 year guarantee offered on these products.

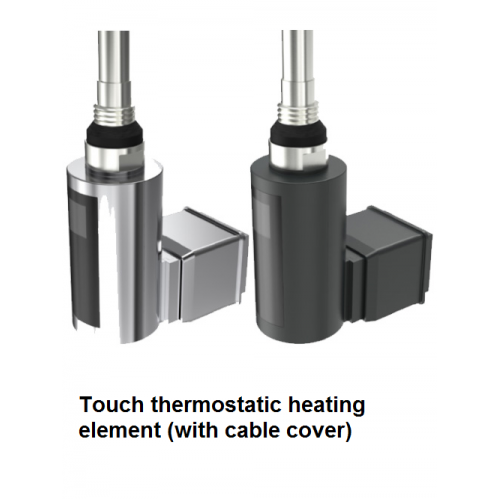

How does the capacitive interface on the Touch Control Element function and is it safe for bathroom environments?

The Touch Control Element uses a capacitive touch interface similar to a smartphone, which detects the electrical charge of your fingertip through the glass or plastic faceplate. Because there are no physical buttons or moving mechanical parts to let water in, these units are highly resistant to moisture ingress. They generally carry a high IP rating (Ingress Protection), making them safe for installation in bathroom Zones 1 and 2, provided they are hardwired into a fused spur by a qualified electrician in accordance with IEE wiring regulations.

What is the difference between the ELMOOT On Off Touch Element and a fully variable thermostatic model?

The ELMOOT On Off Touch Element is a simplified controller that offers binary operation. It activates the heating coil to run at full designated power until manually turned off or a set timer expires. In contrast, a fully variable thermostatic model allows you to select a specific target temperature (e.g., 45 degrees Celsius). The thermostatic model uses a probe to read the water temperature and cycles the power on and off dynamically to maintain that exact level, whereas the ELMOOT simply provides constant heat input without temperature modulation.

How do I reset the Weekly Thermostatic Element if the display shows an error or the screen is unresponsive?

If the digital interface becomes unresponsive or displays an error code, it may be due to a power surge or a software glitch in the microprocessor. To perform a hard reset, isolate the power supply to the element at the fused spur or the main consumer unit circuit breaker. Leave the power off for at least 30 seconds to allow the internal capacitors to discharge completely. When power is restored, the unit will reboot its operating system. If the problem persists, check that the heating medium fluid level is sufficient, as running an element dry can trigger a permanent thermal safety cut out.